Background

Mining has long been a significant primary sector industry in many countries, for example, Australia. Ventilation is the bedrock of oxygen supply and the primary method of removing hazardous gas in underground mining. Most of the ventilation systems are designed for “worst-case scenarios" and mine managers tend to operate their ventilation system at this peak level without consideration of actual ventilation demand. Therefore, ventilation accounts for a nonnegligible percent of the overall underground energy consumption, but most of them are redundant. As a result, It’s necessary to develop a ventilation-on-demand system to reduce energy consumption and keep a safe environment for workers. However, the deployment of smart environmental data acquisition and ventilation control systems in underground mines remains challenging. Hence, to handle the challenge, Milesight conceives a solution to enhance smart ventilation control for underground mining with LoRa technology.

Why LoRa?

Wired networking has a shortage of limited range, high cost, high maintenance cost and vulnerability in the mining environment. Short-range solutions such as Wi-Fi and Bluetooth fail to cover sufficient areas and have high power consumption and the inability to penetrate deep under the mine environment. The ability of deep penetration of LoRa enables data communication over a long range while using very little power, making it ideal for smart underground mining applications.

Solution

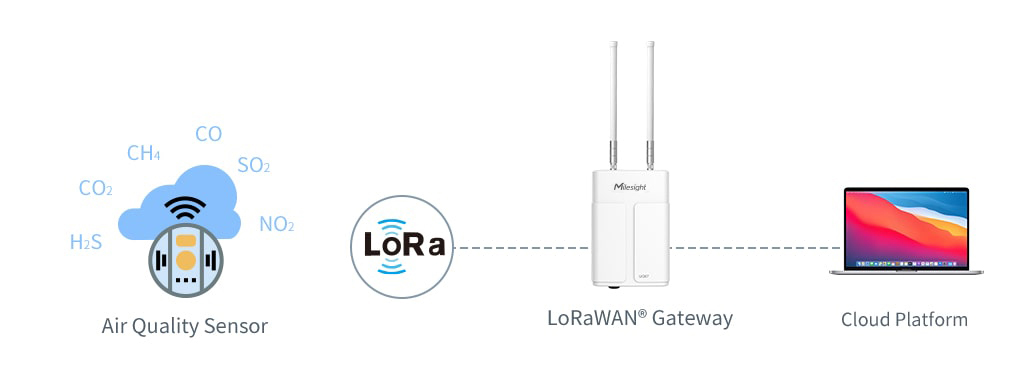

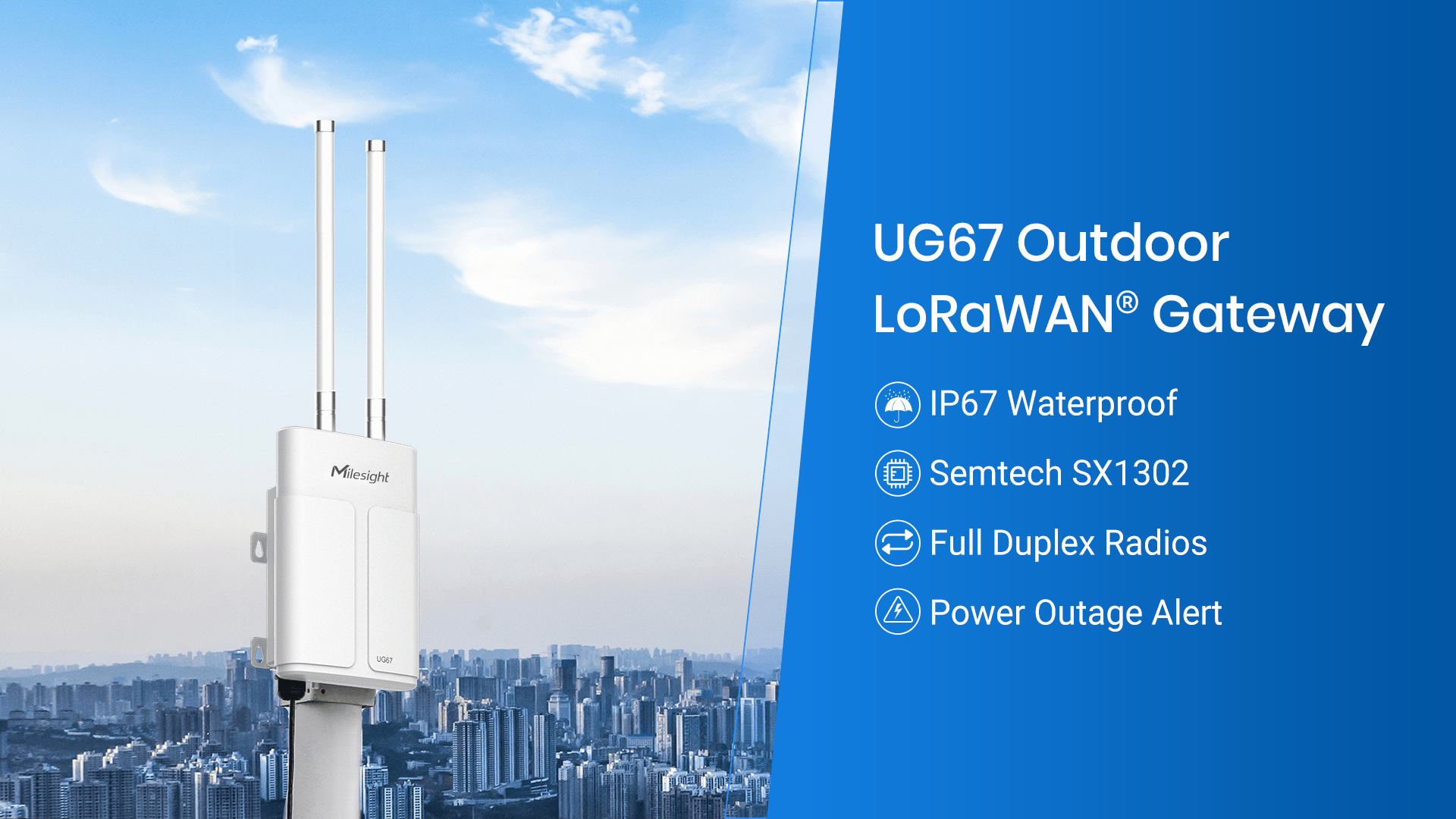

The smart ventilation system is designed to achieve the goal of dynamic control of the ventilation system based on the measured hazardous gas concentration. Air quality sensors are used to monitor concentrations of CO2, CH4, CO, SO2, H2S, NO2 et al. Monitoring the concentration of gases enables adaptive control of the ventilation. Milesight UG67 LoRaWAN® gateway collects data from sensors, then sends out data to the management center. As a result, the management center can automatically turn on the ventilation fan to dilute and remove pollutants or close the ventilation fan to save energy.

Featured Product

Benefits

7*24 Real-Time Monitoring

For the safety of workers and the mine itself, it is important to continuously and accurately monitor the mine environment 7*24.

Reduce Downtime After-blast

Instantly inform operators of environmental safety conditions and hazards. Reduce unnecessary wait times and enable quick turnaround after blasts to increase productivity.

Less Energy Consumption

On-demanded ventilation reduces the unnecessary amount of ventilation in the mine, saving up to 50% energy cost.