Cold Chain Temperature Monitoring:

Ensuring Product Safety Every Step

of the Way

Cold chain temperature monitoring involves monitoring the temperature of perishable goods like food, pharmaceuticals, and biologics from production to delivery. This ensures that these sensitive products stay within the right temperature ranges, preserving their quality, safety, and effectiveness.

Milesight temperature monitoring sensors provide accurate data and a stable connection, enabling organizations to quickly detect and respond to temperature fluctuations throughout the cold chain process. With reliable product performance, we help prevent spoilage and ensure compliance with regulations, especially in the pharmaceutical and food industries.

Why is Cold Chain Monitoring Temperature Important?

Product Safety and Quality

Cold chain monitoring is essential for ensuring the safety and quality of temperature-sensitive products like food, pharmaceuticals, and chemicals. By continuously monitoring temperature and humidity throughout production, transport, and storage, the industry can prevent spoilage, contamination, and degradation.

In the United States, it's estimated that 30% to 40% of the food supply is wasted, and this happens at every stage of the food production and supply chain. One critical factor in reducing this waste is maintaining strict temperature control throughout the supply chain. Cold chain temperature monitoring solutions play a key role in keeping products fresh, preserving their potency, minimizing the growth of harmful bacteria, and ensuring that safe, high-quality products reach customers.

Regulatory Compliance

Temperature control in cold chains is crucial for meeting regulatory requirements, particularly in industries dealing with temperature-sensitive products like pharmaceuticals, food, and chemicals. These regulations mandate strict temperature control to ensure product safety and efficacy.

For instance, CFR Title 21 outlines the required temperatures for transporting biological products. Whole blood-based products, for example, must be transported from the collection facility to the processing facility in an environment that continuously cools the blood to 1 to 10°C or, if necessary, 20 to 24°C for no more than six hours. Blood transported from storage facilities must be kept in an environment that maintains a temperature range of 1 to 10°C during transport.

An effective temperature monitoring solution can help companies monitor cold chain compliance by maintaining critical storage and transport conditions. It can also provide clear records that demonstrate compliance with regulatory requirements.

See How Does Milesight Help Companies Comply>>>

Cost Saving

Cold chain monitoring devices improve cost efficiency by reducing waste and minimizing product loss. By accurately tracking supply chain temperatures, companies can avoid spoilage and degradation of temperature-sensitive goods, which helps cut down on expensive recalls and disposals. Real-time temperature monitoring also allows for proactive maintenance and better resource use, which lowers energy costs and extends the lifespan of refrigeration equipment.

When Is Cold Chain Temperature Monitoring Required?

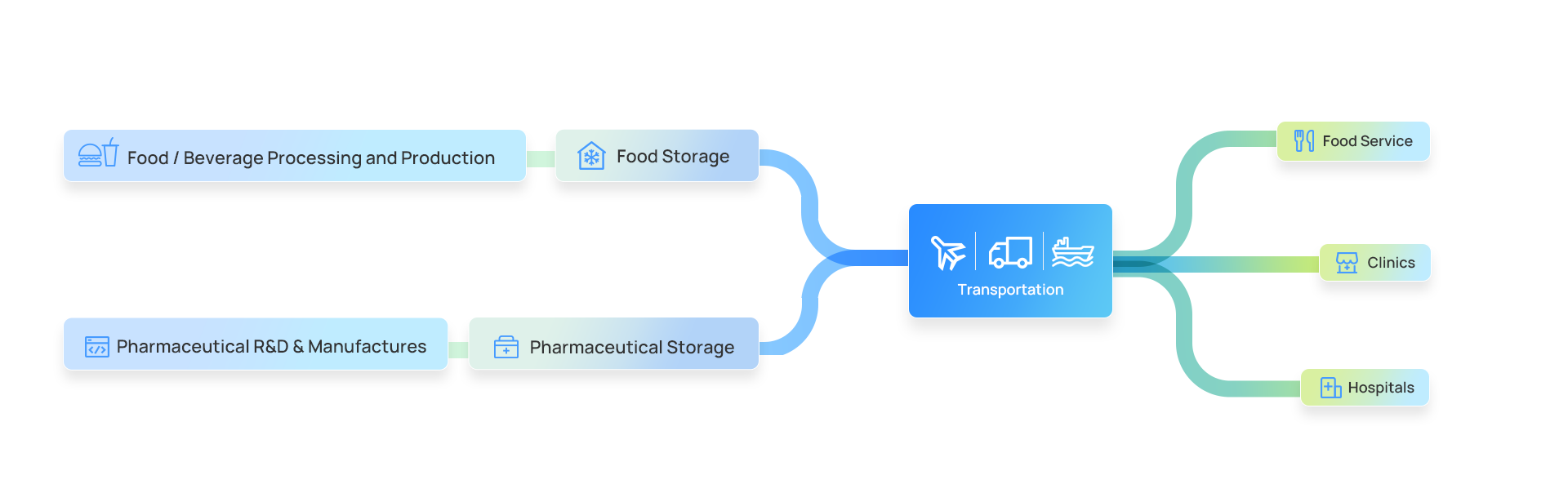

Cold chain temperature monitoring is essential for temperature-sensitive products, especially in the pharmaceutical, food, biotechnology, and chemical industries. Cold chain monitoring systems ensure that products remain safe and effective at every stage, from production to delivery.

Manufacturing Process

Temperature monitoring during production, processing, and handling ensures that raw materials are used under the correct temperature and humidity conditions, helping to maintain product quality throughout the process.

Transportation

Temperature monitoring for cold chain logistics is crucial for perishable goods, especially when crossing different climates. Keeping products at the required temperatures preserves their texture and quality and extends shelf life, particularly for frozen food and fresh produce. Continuous monitoring during transport allows for real-time detection of any temperature excursions and deviations, enabling timely corrective actions to prevent waste.

Storage

Storage temperature detection is crucial for maintaining product integrity. Cold chain temperature monitoring devices track and record data to ensure compliance with required conditions in low-temperature storage environments like medical refrigerators, cold rooms, freezers, and warehouses.

See How Milesight Solutions Work at Cold Chain Supply>>>

Key Features of Effective Cold Chain Temperature Monitoring Solutions

Sensitivity and Accuracy

In a good cold chain temperature monitoring system, the sensitivity and accuracy of sensors are crucial. These sensors must catch even the smallest temperature changes to keep perishable items like vaccines, pharmaceuticals, and fresh produce, at the right temperature.

For instance, in pharmaceutical storage, where items like insulin are kept in cold rooms, even small temperature changes can spoil a whole batch. Accurate sensors are crucial here to stick to strict temperature limits, usually allowing only a one-degree Fahrenheit change. Similarly, in fresh seafood shipments, where products are packed in refrigerated containers, precise monitoring ensures the entire container stays cool and prevents spoilage.

Milesight temperature and humidity sensors are designed to excel in a wide range of cold chain applications. We offer sensors with various temperature detection ranges and levels of accuracy to meet diverse customer needs. For instance, the Milesight EM320-TH can achieve an accuracy of ±0.2°C (0.36°F).

With this high level of accuracy and sensitivity, Milesight cold chain sensors provide reliable, real-time data, ensuring the quality and safety of temperature-sensitive products across critical applications.

Real-time Alerts

Alarms and notifications are the first defense in cold chain monitoring. Sensors track temperature and humidity, detecting even tiny changes. When something goes wrong, alerts quickly highlight abnormal temperatures in specific areas. This allows for quick action to prevent spoilage. Real-time notifications ensure that issues are addressed immediately, keeping temperature-sensitive products safe and high-quality throughout the cold chain.

Milesight temperature and humidity sensors support real-time alerts, immediately notifying users of potential threats like sudden temperature rises or door openings. Data is quickly transferred to the cloud for easy access and retrieval, helping to minimize stock loss in fridges and freezers.

Data Logging and Reporting

Data logging is essential for keeping track of temperature-sensitive products. Sensors continuously monitor and record temperature and humidity, creating detailed logs of storage and transport conditions. These records provide a reliable history that can be checked to ensure compliance with regulations.

For example, if a batch of vaccines might have been exposed to the wrong temperatures, the recorded data can show if and when deviations happened. This helps in making informed decisions about the batch’s viability.

Milesight temperature and humidity sensors provide accurate and comprehensive data logging, with our TS30X series supporting PDF report output to prevent tampering. Our sensors not only ensure product safety but also offer the transparency needed for auditing, quality control, and customer assurance.

Remote access

Remote access allows users to monitor and respond to temperature and humidity conditions from a centralized platform, whether on a computer, tablet, or smartphone. This capability is crucial in situations that require immediate action, such as transporting pharmaceuticals or perishable foods over long distances. In large operations, like managing multiple storage facilities or transport vehicles, remote access ensures continuous monitoring of all locations, reducing the risk of unintentional temperature deviations.

Milesight products can connect to the Milesight IoT Cloud for cloud data management, enhancing the efficiency and reliability of cold chain systems. By providing real-time visibility, control, and remote access, they help safeguard the quality and security of temperature-sensitive products throughout the supply chain.

See More Advanced Features of Milesight Temperature Monitoring Series>>>

How Does Milesight Help Companies Comply in Cold Chain Temperature Monitoring?

Essential Certifications for Cold Chain Compliance

HACCP

This is the most common and important system in the food cold chain. In countries like the United States, the United Kingdom, South Korea, and Australia, HACCP compliance is mandatory for food businesses. Products supporting HACCP include TS30x, TS201, and EM320-TH.

EN12830

EN12830 is the European standard for cold chain temperature measurement equipment, applicable to both food and pharmaceuticals. Milesight's products supporting EN12830 include TS30x, TS201, EM320-TH, and EM300-TH.

21 CFR Part 11

This regulation is specific to pharmaceutical cold chain systems, focusing on preventing data tampering. It requires that temperature measurement data be securely stored, which is critical in the pharmaceutical industry. While this requirement pertains to the cloud, the TS30x supports PDF export to help make data tamper-proof.

FDA Approved

Products like the TS30x and EM320-TH are FDA-approved for manufacturing with food contact materials, ensuring that no harmful substances are introduced into the food processing environment.

Ensuring Precision: Calibration for Cold Chain Temperature Sensors

The cold chain industry accepts both factory and laboratory calibration, depending on industry requirements or product storage risks. The food industry generally has lower calibration requirements, with most equipment accepting factory calibration.

In the pharmaceutical industry, laboratory calibration is often required, and it must be accredited to ISO 17025. Calibration equipment needs to be traceable to national standards. Models like the EM320-TH, EM300-TH, and EM500-PT100 have ISO 17025 accreditation.

Pharmaceutical companies need to calibrate their equipment once a year, based on feedback from competitors and customers. The Health Bureau asks for calibration records during audits, but there’s no strict rule about how often calibration must be done. The Milesight TS201 helps with this by featuring a separate DS18B20 probe that can be sent for independent laboratory calibration.

See Comprehensive Milesight Products to Meet Your Needs>>>

Success Stories with Milesight Temperature & Humidity Sensors

Cold Storage Monitoring and Control for Health Centers & Clinics in Spain

Over 100 Milesight devices were deployed in a pilot health center in Spain, covering an area of over 10,000 km² and serving a population of 1 million. The EM300-TH Temperature & Humidity Sensors were installed to monitor the storage conditions of medicines and vaccines and ensure an optimal environment. If any storage conditions deviate from the ideal, the staff can make timely adjustments to restore them to the correct state. Learn more about the case details here.

Medical Sample Temperature Monitoring for the Largest Hospital in Turkey

Etlik City Hospital deploys Milesight EM300-TH sensors to measure the temperature and humidity of the refrigerators in its laboratories. When the fridges operate at an improper temperature, the staff will get immediate notifications via Telegram. Meanwhile, EM500-PT100 sensors were also used for medical samples that need to be stored at -80°C. These sensors send the ambient data to IoSphere IoT platform which offers real-time status and historical tracking records. Learn more here.

Vaccine Storage Temperature Monitoring in Indonesia

In Indonesia, pharmaceutical experts and system integrators collaborated with the public health department to implement a LoRaWAN-based temperature monitoring system. EM500-PT100 temperature probes were installed in refrigeration units and freezers, continuously logging temperatures and generating alarms to ensure 24/7 protection of valuable vaccine supplies. See how Milesight helps local pharmacies and hospitals stay compliant with the national requirements.

See More Milesight Temperature Monitoring Success Stories >>

Frequently Asked Questions

Which industries particularly need effective cold chain temperature monitoring solutions?

Industries that require effective cold chain temperature monitoring include pharmaceuticals, food and beverage, and chemicals.

In the pharmaceutical industry, precise temperature control is vital to maintaining the efficacy of vaccines, biologics, and other temperature-sensitive medications. For example, vaccines often need to be stored between 2°C and 8°C, and any deviations can compromise their effectiveness.

In the food and beverage industry, cold chain monitoring is essential to keep perishable goods like dairy, meat, and produce safe and fresh from farm to table. Seafood, for instance, typically needs to be stored below 4°C to prevent spoilage and contamination.

Similarly, the chemical industry relies on cold chain monitoring to ensure the stability and safety of temperature-sensitive chemicals, such as certain reagents and solvents that can degrade or become hazardous if not kept within specific temperature ranges.

These solutions help prevent product loss, ensure regulatory compliance, and protect consumer safety across these industries.

Are Milesight Temperature and Humidity Sensors water-resistant for cold chain applications?

Yes, the TS101, EM320-TH, EM300-TH and EM500-PT100 transceivers are IP67 rated. the TS30x is IP65 rated. It is worth mentioning that the EM320-TH can withstand a high-pressure water jet, which is ideal for cold chain temperature detection.

How do Milesight sensors ensure data integrity during cold chain supply?

In addition to regularly reporting data to our customers, our sensors can locally store thousands of historical data records. They also support features like backhaul and retransmission in case of disconnection, ensuring the integrity and reliability of our customer's data.

Milesight Related Products

EM320-TH

Temperature and Humidity Sensor:A Huge Leap for Trustworthy and Holistic Solutions

Explore More

TS301/TS302 LoRaWAN®

Temperature Sensor :TempSecure: Safeguarding Freshness, Ensuring Wellness

Explore MoreIf you are interested in Milesight, please leave us a message.

Contact Us

Contact Us

Contact Us to Get More Information