Understanding PT100 Temperature Sensors:

Platinum-Based Precision for

Industrial Applications

In today's fast-paced industrial and technological world, precise temperature monitoring has become more critical than ever. Whether in manufacturing, food processing, or healthcare, maintaining accurate temperature control is often the key to success. Known for their exceptional accuracy and reliability, PT100 temperature sensors have become the go-to choice across various industries.

The PT100 temperature sensor works by measuring the resistance of platinum, a material known for its stability and precision. The sensor's resistance changes predictably as temperature changes, delivering highly accurate and consistent measurements. This level of precision is crucial in applications where exact temperature control is non-negotiable. Whether safeguarding temperature-sensitive products or ensuring regulatory compliance, PT100 sensors provide a reliable solution for industries that demand the highest standards in temperature monitoring.

What Is a PT100 Temperature Sensor and How Does It Work?

A PT100 temperature sensor is a highly accurate and reliable device used to measure temperature across a wide range of industrial and scientific applications. The name "PT100" is derived from its key characteristics: "PT" stands for platinum, the material used in the sensor, and "100" refers to its resistance of 100 ohms at 0°C. As the temperature rises, the sensor's resistance increases, providing precise and linear output directly proportional to the temperature.

The choice of platinum as the sensing element is not arbitrary. Platinum is a noble metal with excellent stability and repeatability over a wide temperature range, typically from -200°C to +850°C. These properties make PT100 sensors ideal for applications requiring high accuracy, such as in laboratories, industrial processes, and environmental monitoring.

PT100 sensors are a type of resistance temperature detector (RTD), which means they operate on the principle that the electrical resistance of a material changes with temperature. In PT100 sensors, this change in resistance is predictable and follows a well-defined curve, known as the resistance-temperature relationship. This standardized relationship allows PT100 sensors to be easily calibrated and offers consistent performance across different devices and setups.

One of the key advantages of PT100 sensors is their ability to provide highly accurate temperature readings. These sensors are known for their low drift and excellent long-term stability, which are crucial for maintaining consistent temperature monitoring over time. Furthermore, PT100 sensors are less susceptible to electrical noise and interference compared to thermocouples, making them suitable for use in environments where signal integrity is critical.

In summary, a PT100 temperature sensor is a platinum-based RTD known for its accuracy, stability, and wide temperature range. It is an essential tool in industries where precise temperature control is critical, and its standardized characteristics make it a reliable choice for a variety of applications.

Key Applications of PT100 Temperature Sensors

Industrial Applications

PT100 temperature sensors are essential in industrial environments where precision is critical, particularly in applications with extreme temperature demands. These industrial temperature sensors are widely used in manufacturing, chemical plants, industrial boilers, and power generation, where accurate temperature monitoring is crucial for ensuring product quality, safety, and energy efficiency. In industries such as chemical processing, where temperatures can vary widely from extremely high to low, precise control is crucial for reaction management, hazard prevention, and optimized output.

The reliability and accuracy of PT100 sensors make them ideal for such demanding applications, where even minor deviations can cause significant operational issues. Their robust performance in harsh industrial environments, including extreme temperature ranges, and excellent response time, highlights their importance in ensuring consistent and safe operations.

Food & Beverage Industry

In the food and beverage industry, maintaining precise temperature control is crucial for ensuring product safety and quality. PT100 sensors are commonly used in critical processes such as pasteurization, fermentation, and cold chain supply. These sensors provide accurate and reliable temperature readings, ensuring compliance with HACCP (Hazard Analysis and Critical Control Points) standards, 21 CFR Part 11, EN12830, and FDA certification, thereby helping to prevent foodborne illnesses.

For example, in dairy processing, PT100 sensors ensure milk is pasteurized at the correct temperature to eliminate harmful bacteria. The consistent performance of PT100 sensors in environments with stringent temperature requirements makes them an invaluable tool for the food industry.

Healthcare & Pharmaceuticals

In the healthcare and pharmaceutical sectors, PT100 temperature sensors are crucial in maintaining the integrity of temperature-sensitive products and environments. These sensors are used in medical refrigeration, laboratories, and pharmaceutical manufacturing to ensure that vaccines, medications, and biological samples are stored and processed at the correct temperatures.

For instance, in blood banks, PT100 sensors monitor storage units to prevent temperature excursions that could compromise blood quality. The high accuracy and stability of PT100 sensors make them essential for meeting the rigorous standards of healthcare and pharmaceutical industries, where patient safety and product efficacy depend on precise temperature control.

Why Choose Milesight PT100 Temperature Sensors for Precise Monitoring?

The Milesight PT100 temperature sensors are designed to deliver outstanding accuracy and reliability in temperature monitoring. Built with advanced technology, these sensors perform exceptionally well in various industrial and commercial settings.

The following sections will detail the key features that contribute to the superior performance of Milesight PT100 sensors.

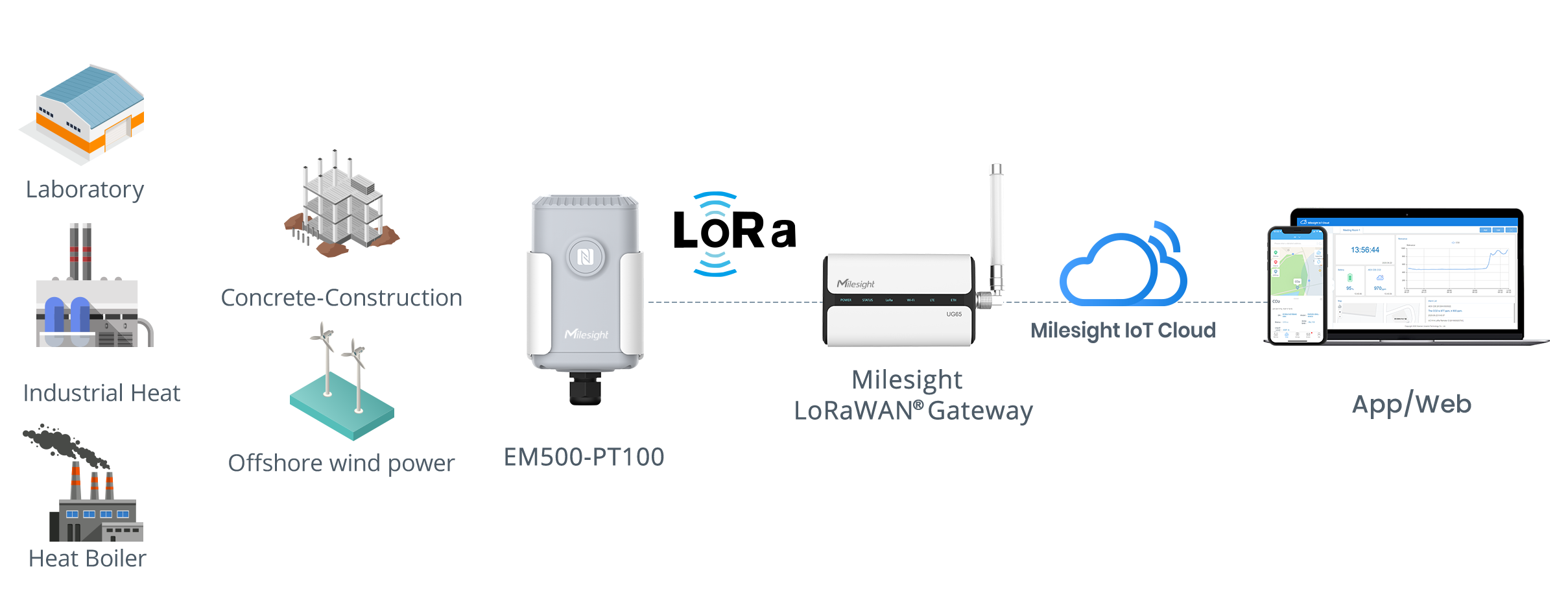

EM500-PT100 Platinum Temperature Sensor

EM500-PT100 platinum temperature sensor is designed to perform in a range of challenging environments. It's an ideal choice for ultra-cold freezers operating at -80°C, where maintaining precise temperature control is essential. This sensor is also extensively used in refining and petrochemical industries, where accurate monitoring is key to ensuring safety and efficiency. In the power and energy sectors, the EM500-PT100 delivers reliable performance, even in high-vibration settings like turbines, pumps, and compressors. Additionally, it’s a dependable solution for plant processing operations that demand consistent and accurate temperature readings.

1) Excellent Accuracy for Extreme Temperatures

The PT100 is one of the most accurate temperature sensors. There are three different ways to measure resistance: a 2-wire, 3-wire, or 4-wire connection. The 2-wire connection is generally suitable for very low-accuracy measurements because any wire or connection resistance will introduce errors in the results.

Any normal process measurement should be done using a 3-wire connection at least. And Milesight EM500-PT100 is making use of 3-wire connection measurement for compensating the cable resistance, to guarantee the accuracy of collected temperature data.

2) Platinum Probes for a Wide Temperature Range

Platinum has a positive resistance temperature factor; resistance increases with rising temperature. Although platinum is a precious metal and therefore very expensive, it delivers greater linearity and stability than any other material.

Milesight EM500-PT100 measures temperature range from -50 to +200°C by default and can expand that range from -200 to a high temperature of +800°C through different sub-models.

3) Adapted Design for a Multitude of Applications

The EM500-PT100 comes with a couple of types of high-accuracy platinum resistance thermometer probes.

The straight tube type of EM500-PT100 probe can be used in common industrial sectors such as measuring operations in extremely humid atmospheric conditions.

Besides that straight tube type, you can also get some other types of probes including the armored, the pressure ring, the magnet, the threaded and SMT, etc by customizing service. They can also help EM500-PT100 sensors work smoothly in applications affected by vibrations, and minimize the impact from turbines, pumps, compressors, and other industrial equipment.

Furthermore, the independent lithium battery inside this sensor makes it relatively immune to electrical noise and therefore is well suited for temperature measurement in harsh industrial environments.

4) Response time

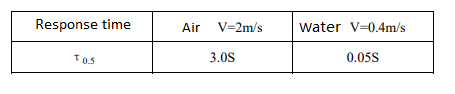

When temperature changes with stages, the output of the thermocouple will be changed to 50% of this stage variation, the required time is called heat response time, represented in τ0.5.

The factors that affect τ0.5 are related to the material, diameter, and thickness of the protective tube, as well as its structure, installation method, insertion depth, and the flow rate and type of the measured medium. This feature makes it extremely suitable for industrial, food, and other applications that require rapid temperature response.

Typical data values of component response time are as follows:

5) RTD vs Thermocouple / Thermistor

Finally, another frequently asked question by customers is the differences between RTD and thermocouple or thermistor. Well, each kind of temperature sensor has its marketing position and best-suited circumstances. The Resistance Temperature Detector offers several advantages such as:

a. The wide temperature range

b. Better accuracy than thermocouples

c. Long-term stability

d. High Accuracy: Class A Per IEC 60751

For more details or to explore our product offerings, please contact us or view our product specifications.

TS302 LoRaWAN® Temperature Sensor

Milesight TS30x LoRaWAN temperature sensors are designed to measure and monitor the temperature of food products, cold chain logistics, and vaccines during various stages of production, storage, and preparation to ensure safety and quality. Ensuring that the temperature remains within acceptable limits is crucial for maintaining product quality, safety, and regulatory compliance.

Milesight TS30x series contains the TS301 Single-Channel Version and the TS302 Dual-Channel Version. The TS302 supports simultaneous connection of both a PT100 temperature probe and a door magnetic sensor, or two PT100 temperature probes for specialized applications. The probe also shares the same advanced features as the EM500-PT100, ensuring reliable performance in demanding environments.

Meanwhile, the TS30x series features can process up to 10,000 sets of historical data records, as well as the retrieval and retransmission of data. It optimizes readability with an LCD screen and is equipped with 5~15 Years of Battery Life that operates over the LoRaWAN® network. What’s more, it is designed with IP65 rating protection and meets HACCP and 21 CFR Part 11B requirements.

To learn more about how TS30x can benefit your operations or to request detailed product information, please leave a message or view our product details.

For a detailed comparison between the Milesight EM500-PT100 and the TS30x series PT100 temperature sensors, you can get a free consultation or refer to our full Temperature and Humidity Sensors Comparison Guide.

How to Choose the Right PT100 Temperature Sensor for Your Needs?

Let's go over the top 7 factors that you need to consider when picking up the right Platinum Resistance Thermometers or RTDs or Pt100 RTD sensors for your application.

RTD Element Type

Do you know the RTD element type? Besides the platinum PT100 or PT1000, other materials such as nickel, nickel-iron alloy, and copper have also been used for RTDs. Regardless of the medium that you are connecting the RTD sensor to, this factor must be first confirmed.

Measuring Medium

Determine whether the sensor will be used for measuring gas, liquid, or material surfaces. Identify the deployment location for the probe. Specify if the probe needs to be placed inside a container or secured with a fastening method.

Temperature Range

This is the fundamental factor as it determines the element type and the submodels from the EM500-PT100 model from -200 to 800°C.

Deployment Location

Choose the appropriate probe type based on your deployment location. Options include wall mounting, pressure rings, magnetic attachments, and surface mount technology (SMT). The right probe type ensures effective integration into your setup.

Working Environment

Is the IP67 rating and anti-corrosive protection enough for you? Do you need it to be ATEX-approved, safe for food production, and against vibration?

Physical Considerations

Specify the length, diameter, and size requirements of the sensor. Determine if the sensor needs to be bent or if it must be exceptionally long.

Wire Connection

You also need to ensure that a 2-wire connection is enough for you. Or do you need more accurate data provided by 3-wire or 4-wire connect?

Success Story

Power Plant Temperature Monitoring

At a major Chinese power plant, Milesight's EM500-PT100 sensors and UG65 gateway were implemented to enhance temperature monitoring of critical equipment. This advanced system provided accurate real-time temperature data, significantly improving operational safety and efficiency.

By optimizing temperature monitoring in harsh industrial environments, the solution effectively reduced the risk of equipment failures and streamlined maintenance processes, demonstrating the reliability and effectiveness of Milesight sensors in demanding industrial applications.

For more details, you can check out the full story here.

Vaccine Storage Temperature Control

Milesight's temperature monitoring solution was implemented to ensure the safe storage of vaccines in a critical healthcare facility. Using the EM500-PT100 sensors, the system provided precise 24/7 real-time temperature data, crucial for maintaining the integrity of sensitive vaccines. This solution not only enhanced the reliability of storage conditions but also ensured compliance with stringent healthcare standards, ultimately safeguarding public health by preventing vaccine spoilage.

For more details, you can check out the full story here.